CNC machining

CNC MACHINING

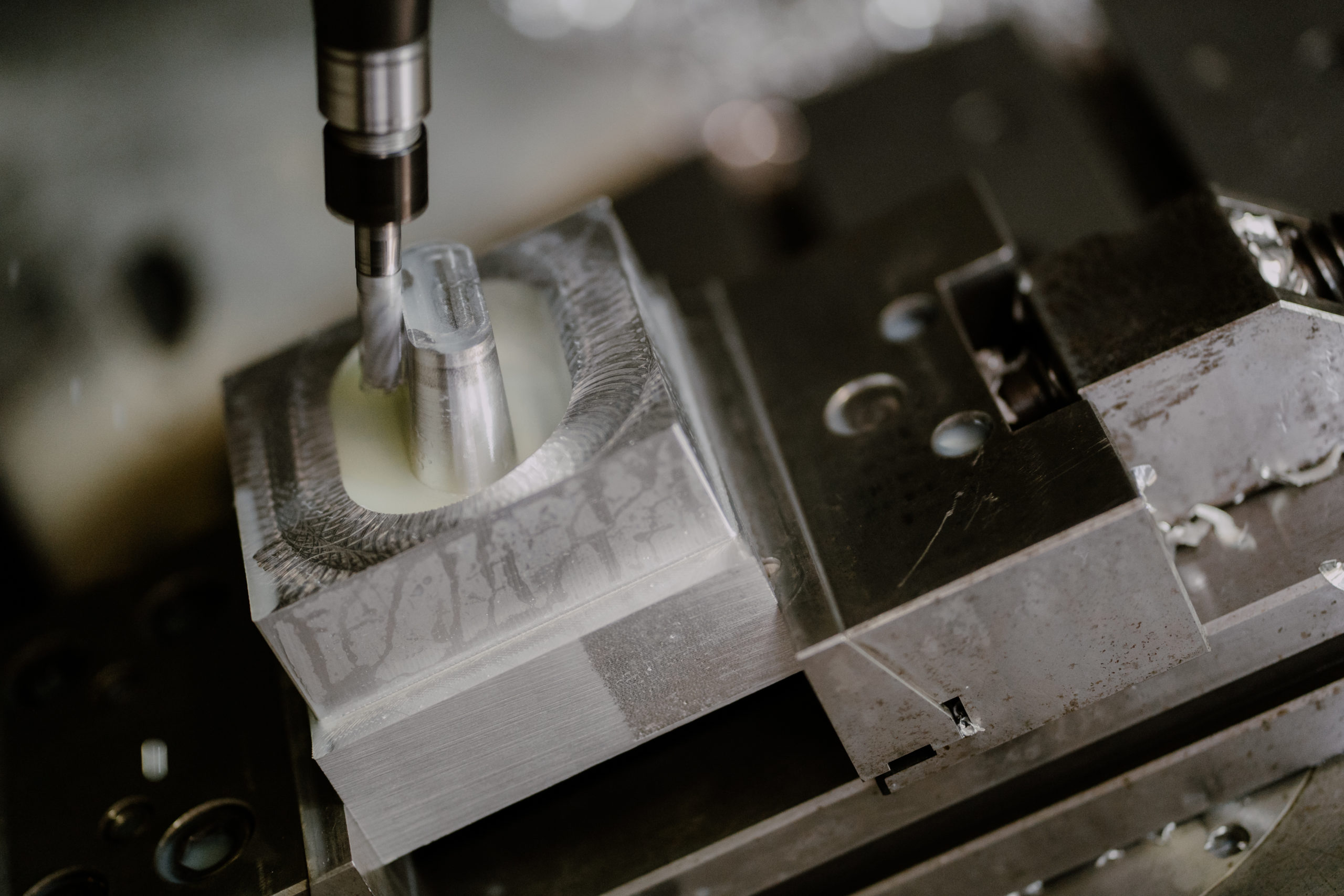

We manufacture foundry tooling, as well as all production parts and tools according to customer requirements.

The technologies we currently use allow us to process components in 5 axes.

The CNC milling process takes place on modern 3,4 and 5-axis milling machines, which gives us the ability to produce parts with:

- lengths of up to 2480 mm,

- widths of up to 1780 mm,

- heights of up to 800 mm.

Larger parts and models are made by dividing them into smaller pieces and then gluing them together (resins, plastics, MDF) or screwing them together in the case of metal parts.

The final stage of production is the manual processing, assembling and completion of the manufactured parts. Manual finishing allows the surface quality needed to produce a casting free of defects and of the highest quality.

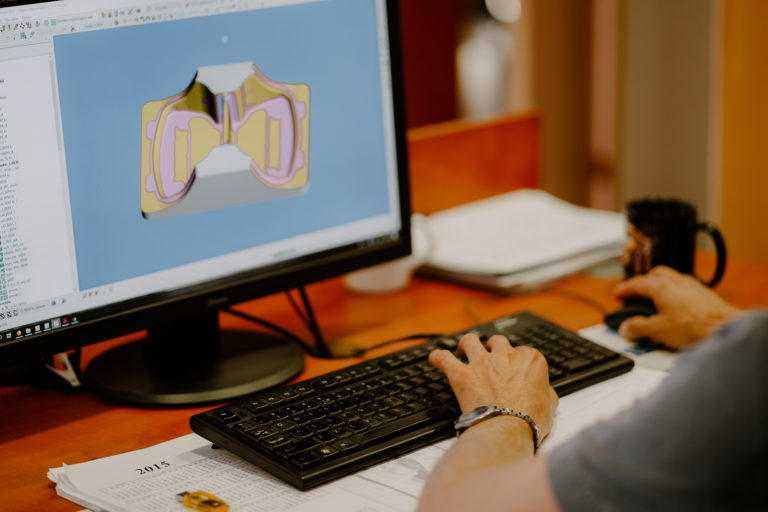

2D/3D DESIGN

In preparing the workpiece for milling, we use some of the most modern systems available on the market:

- CREO (Pro/ENGINEER),

- DELCAM PowerMILL,

- ZW3D.

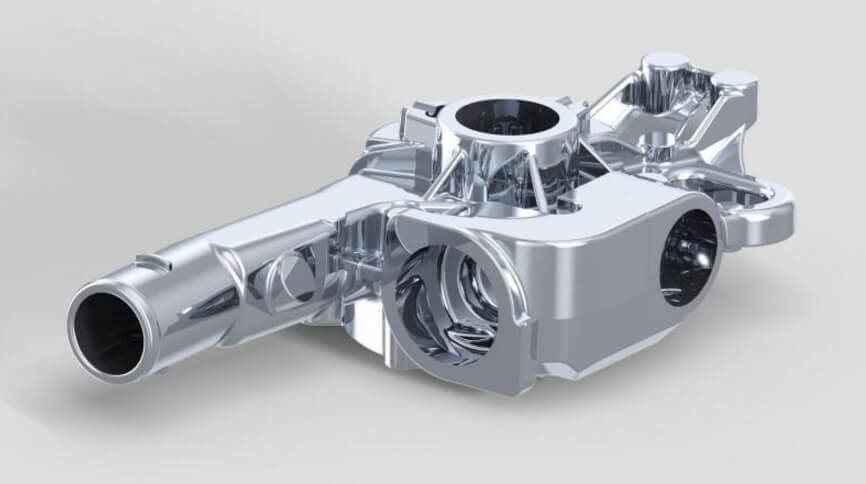

Using this software, we construct virtual 3D models of the components and then create machining programmes for their manufacture.

Our experienced engineers can easily create a 3D solid from the 2D documentation provided and, when required, give it the appropriate ribs, casting inclination, overmoulding and other necessary workpieces to create a top-quality final product.

Machine park

Our extensive machine park includes 3-4 and 5 axis milling machines