Feed mixing plants

Sections of the feed mixing plant

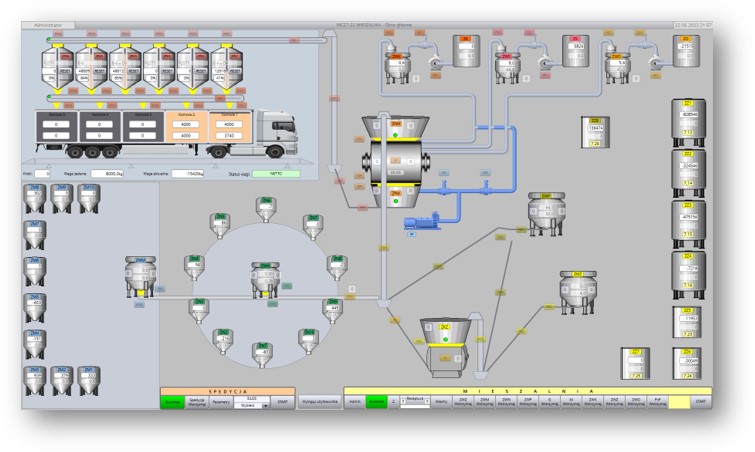

Each feed mixing plant consists of the following sections:

- Section for receiving and loading grains into storage tanks,

- Section for loading raw materials onto component tanks,

- Grain and micro and nano weighing section,

- Raw material preparation and grinding section,

- Feed mixing section,

- Warehousing and shipping section for finished raw material,

The grain weighing station is often additionally equipped with a grain quality testing system. The sample taken from the vehicle is sent to the laboratory, where it is carefully checked so that the grain which arrives at the mixing plant at a later stage is of the best possible quality.

Automation of feed mixing plants

The feed mixing plants are fully automated!

They have the ability to view as well as remotely control via the web.

In addition, by installing a vehicle scale within the mixing plant, the level of automation of the entire process can be further increased, as well as improving the process of receiving and loading components into production silos.

We encourage you to visit the project gallery, where you will find photos of some of our implementations.

The capacity of the feed mixing plant reaches up to 25 tonnes per hour!.

Our current solutions allow us to produce feed not only for poultry, but also for cattle and pigs,

The manufacturer has the option of intervening in its composition and, for example, adding a specific single component,

Thanks to the use of complex automation and software, the mixing plant can operate continuously for up to 24 hours a day, achieving 10 production cycles per hour.

In addition, only one person is needed to operate it!

We are able to adapt each project to the individual needs of the client.

If you have any questions, we are at your disposal.

Order execution process

- One-to-one meeting with the client,

- Presentation by the client of requirements and expectations regarding the mixing plant,

- Initial design outline on site at the client's premises,

- After an initial outline, a 2D design of the mixing plant with all the elements is created,

- The design, together with a quotation, is sent to the client for approval or for any necessary changes,

Once the project is accepted by the client, the terms of installation and the start-up date of the mixing plant are agreed.